Supply Chains’ Increasing Demand on Carbon-Intensive Aluminium

July 23, 2019

Given EV manufacturers’ imperative to reduce vehicle weight in order to offset the heavier battery and maximize energy efficiency, designers and engineers in unprecedented numbers have been reaching for aluminum, triggering an explosion in demand. Its superiority as a lighter-weight alternative to steel is so significant that every 2.2 pounds of aluminum used in a car has been found to reduce the overall weight of the vehicle by 2.2 pounds.

Automakers have long been using aluminum in bumpers, and Tesla uses 0.3-inch bulletproof aluminum alloy sheets to protect its battery compartment and guarantee safety at speeds of up to 120 mph.

Lighter Vehicles

All told, the share of aluminum in the overall weight of an average car has increased from 80 pounds in the 1970s to more than 350 pounds today. By 2025, that figure should reach nearly 600 pounds.

Reducing Emissions

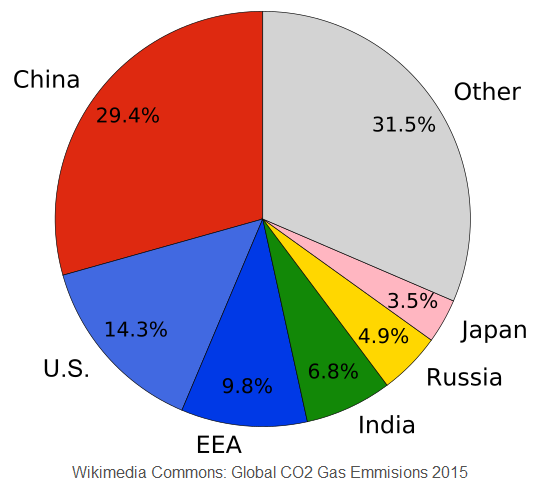

Manufacturing aluminum is energy-intensive. Consequently, in China, where the world’s largest producers are headquartered, smelters that draw electricity from coal-fired power stations can release 22 tons of carbon for each ton of aluminum they produce, because the electricity they use is so polluting and carbon-intensive.

But not all aluminum is created that way. For example, the equivalent carbon emission figure for gas-powered plants in the Middle East is around 8 tons per ton of aluminum produced. Plants that run primarily on renewable energy can produce a ton of aluminum while creating less than 4 tons of CO2.

But even that figure is too high. We are investing to bring emissions well below that by 2025. Meanwhile, the leading innovators in the sector are also seeking to develop inert-anode technology that releases oxygen rather than carbon in the smelting process, with our aim being the roll-out of a commercial, carbon-free aluminum product early in the next decade.

As environmental factors exert an increasing influence over corporate and consumer purchasing decisions, demand from the auto industry for the greenest variants of aluminum can only grow further. This was a key factor behind our decision to partner with Braidy Industries, of Ashland, Ky., to produce flat-rolled aluminum products for the U.S. auto industry — the first new rolling mill in North America in over 37 years.

So what does this all mean? Certainly nearly all major automakers are innovating and doing their best to respond to demand for greener vehicles and to be responsible corporate citizens in the fight against climate change.

Barker, Gregory. (2019). “Aluminum’s carbon footprint is dirty”. Retrieved from https://www.autonews.com/commentary/aluminums-carbon-footprint-dirty.