A Material Revolution is Changing the Manufacturing Industry

January 16, 2019

Materials science may be one of the more important technologies of the next decade. Manufacturers need new materials to create more advanced products. Manufacturers also need to replace materials subject to supply disruptions, like rare earth elements.

Traditionally, developing new materials has been a slow, painstaking process. To find the properties being searched for, researchers would often have to test hundreds — or even thousands — of materials one by one. That made materials research prohibitively expensive for most industries.

Yet today, manufacturing is in the midst of a materials revolution. Scientists are using powerful simulation techniques, as well as machine learning algorithms, to propel innovation forward at blazing speed and even point them toward possibilities they had never considered. Over the next decade, the rapid advancement in materials science will have a massive impact.

Lending a hand in materials science advances is The Materials Project. The Materials Project harnesses the power of super-computing and state of the art electronic structure methods and provides open web-based access to computed information on known and predicted materials as well as powerful analysis tools to inspire and design novel materials. The industry is working together for the sake of expediting progress.

The Materials Project went online early in 2011 and drew a few thousand people. From there it grew like a virus and today has more than 50,000 users, a number that grows by about 50-100 per day. Yet its impact has become even greater than that. The success of the project caught the attention of Tom Kalil, then Deputy Director at the White House Office of Science and Technology Policy, who saw the potential to create a much wider initiative.

In the summer of 2011, the Obama administration announced the Materials Genome Initiative (MGI) to coordinate work across agencies such as the Department of Energy, NASA, the Department of Energy and others. These efforts are creating a revolution in materials science and the impacts are just beginning to be felt by private industry.

The MGI is based on three basic pillars. The first is computational approaches that can accurately predict materials properties. The second is high throughput experimentation to expand materials libraries and the third are programs that mine existing materials in the scientific literature and promote the sharing of materials data.

For example, one project applied machine learning algorithms to experimental materials data to identify forms of a super strong alloy called metallic glass. While scientists have long recognized its value as an alternative to steel and as a protective coating, it is so rare that relatively few forms of it were known. Using the new methods, however, researchers were able to perform the work 200 times faster and identify 20,000 in a single year!

Creating a True Materials Revolution

Thomas Edison famously remarked that if he tried 10,000 experiments that failed, he did not actually consider it a failure, but found 10,000 things that did not work. The new methods of testing, however, have the potential to automate those 10,000 failures, which is creating a revolution in materials science.

The work is also quickly making an impact on Industry. Greg Mulholland, President of Citrine Informatics, a firm that applies machine learning to materials development, stated, “We’ve seen a huge broadening of companies and industries that are contacting us and a new sense of urgency. For companies that historically invested in materials research, they want everything yesterday. For others that haven’t, they are racing to get up to speed.”

Jim Warren, a Director at the Materials Genome Initiative, thinks that is just the start. “When you can discover new materials for hundreds of thousands or millions dollars rather than tens or hundreds of millions you are going to see a vast expansion of use cases and industries that benefit,” he told me.

As we have learned from the digital revolution, any time you get a 10x improvement in efficiency, you end up with a transformative commercial impact. Just about everybody I’ve talked to working in materials thinks that pace of advancement is easily achievable over the next decade.

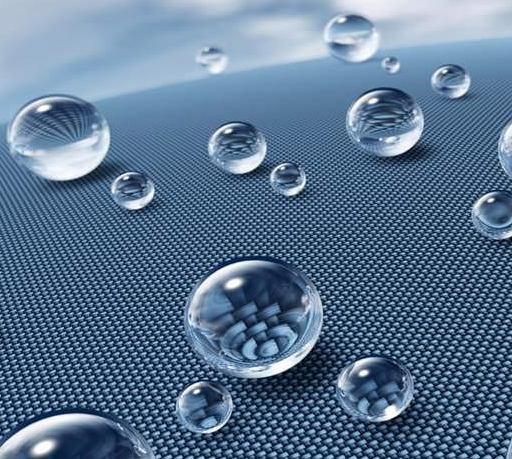

Smart fabrics, coatings stronger than steel, heat-resistant materials, nano-filler composites…welcome to the materials revolution.

Satell, Greg. (2019). “Materials Science May Be The Most Important Technology Of The Next Decade. Here’s Why”. Retrieved from https://www.digitaltonto.com/2019/materials-science-may-be-the-most-important-technology-of-the-next-decade-heres-why/.