Benefits of Virtual Prototyping

November 19, 2018

Virtual reality is not as new as one may think.

In 1935, Stanley Weinbaum released Pygmalion’s Spectacles – a science fiction story. The story’s main character wears a pair of goggles which transports him to a fictional world which stimulates his senses aptly and features holographic recordings. Some consider this to be the origin of the concept of virtual reality. The first technical development of virtual reality was not until the 1950s when cinematographer Morton Heilig created Sensorama, the first VR machine (patented in 1962).

Many advances in virtual reality have been made since, but, a basic principle that every engineer understands has not changed. If a design does not work in the real world, it is a failure. This is where virtual prototyping comes into play.

Prototyping has had an important role in the product development process for manufacturers. Prototyping allows manufacturers greater insight into real-word performance and ensures that major design flaws are identified and mitigated before the final product ships. Unfortunately, the physical “design/build/test” process adds significant cost and time to the product development cycle, sometimes years of costs.

However, today, new simulation tools are freeing engineers from their dependence on costly physical prototypes. Simulation is reducing the number of physical product rebuilds, mitigating material waste, cutting product development cycles and allowing manufacturers to bring quality products to market faster than ever before.

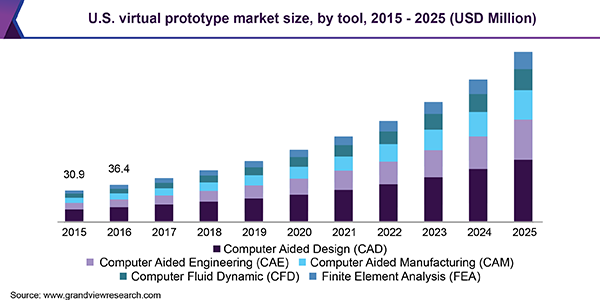

Growing competitiveness and continuous growth in manufacturing, is driving the need for new product development which in turn also fuels the market for virtual prototypes. On the other hand, smaller companies might refrain from virtual prototype solutions at this point of time due to high initial investment and lack of skilled professionals.

Currently, North America and Europe own the majority share in the virtual prototype solutions market.

Virtual prototype tools find application in a variety of industries, including automotive, aerospace, healthcare, consumer electronics, telecom, and others.

The automotive vertical accounted for nearly 34.0% of the global virtual prototype market share in terms of revenue in 2017. This growth can be attributed to the higher adoption of CAD and other virtual prototype tools by Original Equipment Manufacturers (OEMs) to increase efficiency in designing and manufacturing and accurately testing product prototypes before investing in mass production.

Safety is an additional benefit. For manufactures to produce new models and meet increasingly strident safety requirements, development methodologies have had to evolve. Greater use of simulation in hardware and software development and more sophisticated analysis and their implications can ensure that vehicles keep getting safer.

The value of virtual prototyping in product development has many companies relying more on this process with good results. The process has made tremendous strides and has significantly impacted product design. There is no telling what the future holds. There is just no denying that virtual prototyping will take us wherever we are going exponentially faster.